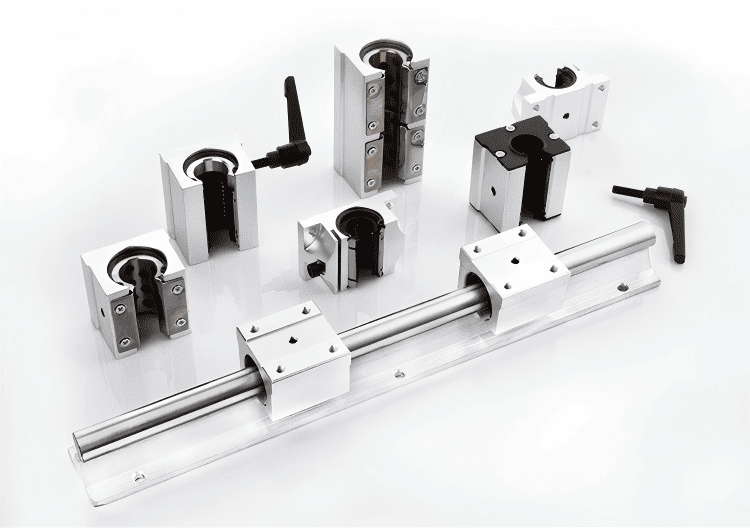

SBR Linear Guides – Precision Motion at Factory Price

Discover cost-effective, customizable SBR linear rails – engineered for smooth performance in CNC routers, 3D printers, and automated machinery. Backed by our own 8-line factory, we offer OEM solutions with fast delivery and strict quality control.

- ✅ Factory-Direct Pricing

- 🚚 Fast Global Shipping

- 🧩 Free Customization

- 🎁 Free Samples Available

Choose Your SBR Block – Tailored to Every Application

Each project has its own demands. That’s why we offer a wide range of SBR bearing blocks—designed with different materials and structures to meet your exact requirements. Whether you’re looking for maintenance-free operation, high load capacity, or dustproof performance, you’ll find the right match here.

🔹 Standard Block

🔹 Extended Block

Designed with extra length to improve guidance and stability. Ideal for long travel distances or heavier payloads.

Best for: Large-scale platforms

Highlights: More support | Better rigidity | Anti-vibration

🔹 Steel Cage Block

Uses a stainless steel cage for higher structural integrity and heat resistance. Perfect for continuous operation or high-load environments.

Best for: Heavy-duty equipment, high-speed automation

Highlights: High rigidity | Long life | Heat-resistant

🔹 Sealed Dustproof Block

Integrated rubber seals on both ends effectively block dust, chips, and moisture. Reduces downtime and extends service life.

Best for: Woodworking, textile machinery, outdoor systems

Highlights: Fully sealed | Low maintenance | Durable

🔹 Brass Sleeve Block

Built with self-lubricating brass bushings for quieter and more stable performance. Great for applications with limited lubrication access.

Best for: 3D printers, experimental setups, lightweight machinery

Highlights: Silent | Low-wear | No frequent oiling

🔹 Aluminum-Plastic Hybrid Block

Maintenance-free block combining an aluminum shell with plastic bearing inserts. Corrosion-resistant and lightweight—ideal for compact or clean environments.

Best for: Food processing, mini CNC, mobile units

Highlights: Rust-proof | Lightweight | No oil required

📌 Need Help Choosing?

Tell us your application and performance requirements. Our engineers will match you with the most suitable block.

Custom SBR Linear Guide Manufacturer and Supplier in China

At Linearlinx, we understand that every motion system is different. As a leading manufacturer of linear guide rails in China, we specialize in offering precise and flexible customization for your specific needs—without driving up your costs.

Custom SBR Linear Guide Solutions Tailored to Your Project

Custom Rail Lengths: Cut precisely from 100mm to 6000mm, with splicing options for longer configurations.

Block Types & Materials: Choose from standard, extended, sealed, brass sleeve, steel cage, or aluminum-plastic blocks.

Bearing Cage Options: Nylon, brass, or stainless steel for durability and environment-specific needs.

Mounting Hole Adjustments: Customize pitch, diameter, and position to ensure perfect machine fit.

Brand Personalization: Add laser logos, sticker labels, or fully branded packaging.

Corrosion Resistance: Anti-rust coating or stainless shafts for humid or food-grade environments.

MOQ-Friendly: Low minimum order quantities for custom designs.

Partner with our experienced engineering team to ensure every detail matches your machine’s requirements. Whether you’re in CNC, packaging, woodworking, or industrial automation—we help your system move better, longer, and more efficiently.

Easily Customize Your SBR Linear Guides with Linearlinx

We’ve simplified the customization process. Our proven 4-step workflow ensures your ideas are fully supported by our design and production teams—every step of the way:

Working Environment

Let us know the conditions your machine runs in—load range, humidity, vibration, exposure to dust or moisture, and operating temperature. This helps us choose the right block structure and materials.

Machine Application

Tell us about your machine type—whether it’s a CNC router, 3D printer, woodworking line, laser cutter, or industrial assembly system. We’ll recommend the most compatible guide configuration.

Select the Block Type

Choose the most suitable SBR block: extended for long-stroke support, sealed for dusty environments, brass for quiet operation, or aluminum for rust-free performance.

Technical Drawings & Specs

Send us your sketches, CAD files, or reference dimensions. We’ll confirm every detail and provide a finalized drawing for approval before production starts.

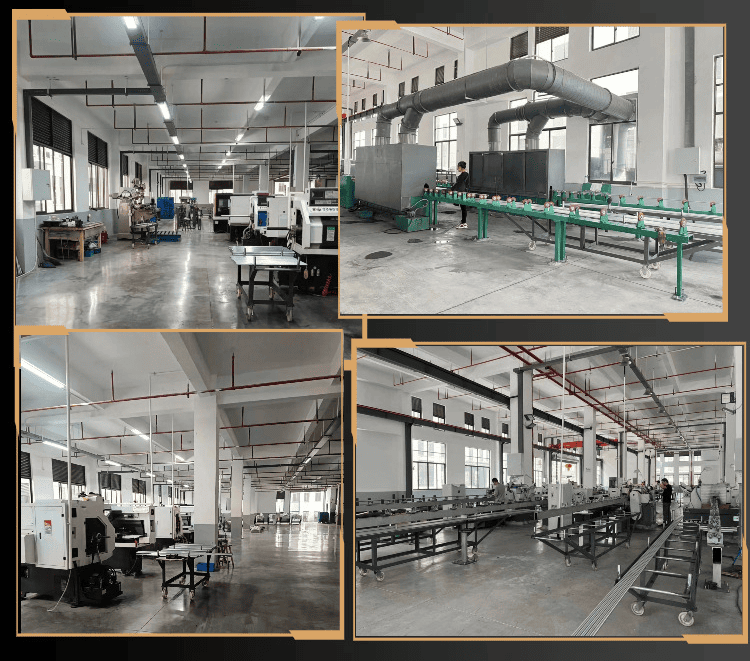

🏭 Why Buyers Worldwide Trust Linearlinx

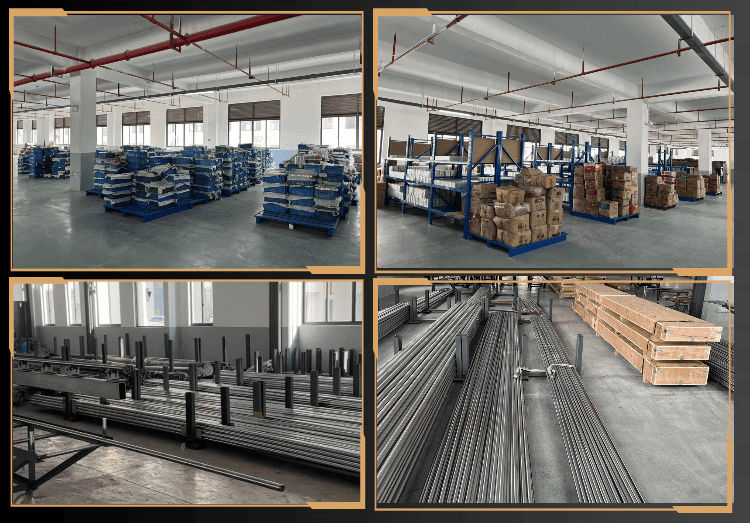

At Linearlinx, we’re not just a trading company—we are the original factory behind the product. With over 200 employees and 8 high-efficiency production lines, we deliver consistent quality, fast lead times, and unmatched flexibility in customization.

From sourcing raw material to final packing, every step happens in-house—giving you control, reliability, and peace of mind.

🏆 Our Competitive Factory Advantages

🔧 In-House Manufacturing

We produce all SBR guide rails and bearing blocks in our own ISO-compliant facility. Zero outsourcing means full quality control.🚀 High Output Capacity

8 production lines | 200+ staff | 6000mm max rail length | Fast sample turnaround🌐 20+ Export Countries

Trusted by clients in the USA, Brazil, Mexico, Indonesia, Russia, Vietnam, and more.🧪 Full Quality Inspection

Each unit is tested for straightness, hardness, precision, and smoothness before shipment.📦 Mix Shipping Supported

Consolidate your order with pillow blocks, shaft supports, and couplings—save freight cost.🎁 Free Samples + Custom Branding

We support laser logo engraving, custom packaging, and OEM labeling at low MOQs.🛡️ Triple Guarantee Policy

In case of confirmed quality issues, we offer up to 3x product value compensation—rarely needed, always reassuring.

🧩 Application-Ready Supply

Our SBR linear rails are already used in:

Whether you’re a reseller, machine integrator, or direct user—we are ready to scale with your business.

❓ Frequently Asked Questions About SBR Linear Guides

A: We offer shaft diameters from 10mm to 50mm, with standard lengths from 100mm to 6000mm. Longer rails can be spliced upon request.

A: Yes! We support full customization: block structure, shaft length, mounting hole pitch, surface treatment, and even logo engraving. Just send us your specs or drawings.

A: For standard models, lead time is 3–7 working days. For custom orders, it's typically 7–15 working days, depending on quantity and complexity.

A: Absolutely. We provide free samples for testing—just let us know the size and shipping address.

A: We offer bulk packaging, individual boxed sets, or custom-branded cartons. Packaging is moisture-proof and suitable for sea/air freight.

A:Sealed blocks offer protection from dust and chips—great for woodworking or textile use.

Brass sleeve blocks are self-lubricating, low-noise, and ideal for light-duty or maintenance-free setups.

A: Yes! We support mixed container loading of rails, blocks, supports, and couplings—helping you save on freight and simplify sourcing.

A: We offer ISO9001, RoHS, Material Inspection Reports, and Certificates of Origin (CO, Form E, F, A, etc.) upon request.

A: Yes. We support full OEM branding including laser logo, custom labels, and outer packaging tailored to your business needs.

Still Have Questions?

We’re happy to assist with any technical, commercial, or shipping inquiries.

在这里添加您的标题文本

我是标签内容,点击编辑按钮更改此文本。Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Table of Contents

在这里添加您的标题文本

我是标签内容,点击编辑按钮更改此文本。Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.